commercial desalination systems have become essential infrastructure for businesses facing water scarcity or requiring high-purity water for operations. These engineered solutions convert seawater or brackish water into fresh water suitable for diverse commercial applications including hospitality facilities, manufacturing plants, office complexes, and agricultural operations. The commercial desalination segment demonstrates strong growth trajectories, with the industrial application sector posting a compound annual growth rate of 10.42 percent through 2030, driven by semiconductor manufacturing, pharmaceutical production, and other water-intensive industries requiring reliable supply independent of municipal infrastructure.

What Distinguishes Commercial Systems From Municipal Installations?

Commercial desalination systems operate at scales between residential units and large municipal plants, typically producing between 1,000 and 500,000 gallons daily depending on facility requirements. These mid-scale installations emphasize operational flexibility, allowing businesses to adjust production rates based on seasonal demand fluctuations or process requirements. Unlike municipal systems with continuous baseload operation, commercial units often incorporate variable-speed drives and modular configurations that optimize energy consumption during periods of lower demand.

The engineering specifications for commercial systems prioritize compact footprints and aesthetic integration into existing facilities. Many commercial installations utilize containerized designs housing all components within standard shipping containers, enabling rapid deployment and minimal civil construction. This approach proves particularly valuable for resort properties, offshore platforms, and remote industrial sites where traditional infrastructure development would prove prohibitively expensive or time-consuming.

?How Do Reverse Osmosis Systems Dominate Commercial Applications

Reverse osmosis technology accounts for the overwhelming majority of commercial desalination installations due to superior energy efficiency and water quality output. These membrane-based systems force pressurized water through semi-permeable barriers that block dissolved salts while permitting water molecules to pass through. Modern commercial reverse osmosis units achieve energy consumption below 3 kilowatt-hours per cubic meter for seawater applications, with brackish water systems operating at substantially lower energy requirements.

Energy recovery devices integrated into commercial systems capture up to 60 percent of the pressure energy from concentrated brine streams, redirecting this energy to pressurize incoming feed water. This innovation dramatically reduces operational costs, making desalination economically competitive with alternative water sources even for price-sensitive commercial applications. Variable frequency drives on pump motors enable precise pressure control that maximizes membrane lifespan while maintaining target production rates.

?Which Industries Require Commercial Desalination Solutions

Hospitality and resort operations represent significant commercial desalination users, particularly properties in coastal regions with limited freshwater infrastructure. Beach resorts, island hotels, and cruise ships rely on onboard or shore-based desalination to provide guests with safe drinking water, support food service operations, and maintain swimming pools and recreational facilities. These applications demand consistent water quality meeting stringent health standards while maintaining operational reliability during peak occupancy periods.

Manufacturing sectors including food processing, beverage production, and pharmaceutical manufacturing increasingly implement commercial desalination systems to ensure water supply reliability and quality consistency. These industries require process water meeting specific purity standards that municipal supplies may not consistently deliver. On-site desalination provides complete control over water characteristics, eliminating risks associated with municipal supply variations or contamination events.

Agriculture operations in water-stressed regions utilize commercial desalination for irrigation, particularly for high-value crops requiring specific water quality parameters. Greenhouse facilities and hydroponic operations benefit from desalinated water free from excessive minerals that would accumulate in growing media or damage sensitive plants. The predictable water quality enables precise nutrient formulation, optimizing crop yields and product quality.

?What About Energy-Intensive Operations

Data centers and electronics manufacturing facilities consume substantial water volumes for cooling systems and ultra-pure production processes. Commercial desalination ensures these operations maintain continuous production capability independent of local water availability or quality variations. The semiconductor industry particularly demands exceptionally pure water with conductivity below 0.1 microsiemens per centimeter, requiring multi-stage treatment combining desalination with ion exchange and electrodeionization.

?How Do Pre-Treatment Systems Protect Equipment Investment

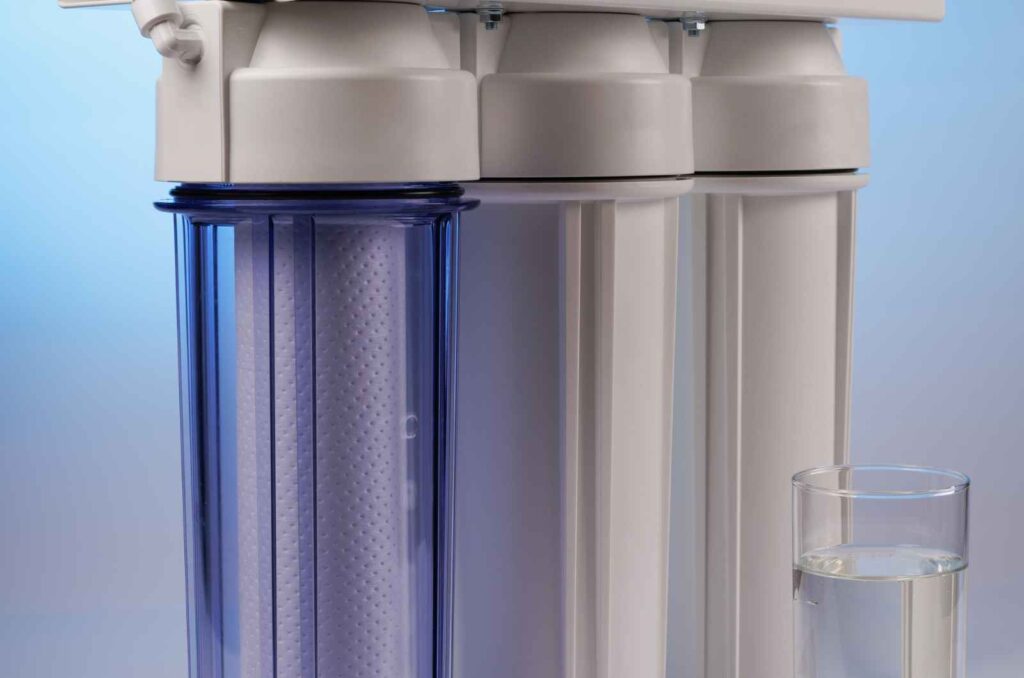

Effective pre-treatment prevents membrane fouling and scaling that would otherwise degrade system performance and necessitate frequent cleaning or premature membrane replacement. Commercial systems typically incorporate multi-stage filtration removing suspended solids, organic matter, and colloidal particles before water contacts reverse osmosis membranes. Cartridge filters with progressively finer ratings provide mechanical protection, while chemical dosing systems adjust pH and sequester scale-forming minerals.

Advanced pre-treatment designs incorporate ultrafiltration or microfiltration membranes providing absolute barriers against particles above specific size thresholds. This approach ensures consistent feed water quality even when source water characteristics fluctuate due to seasonal variations, storm events, or other environmental factors. The investment in robust pre-treatment substantially extends reverse osmosis membrane operational lifespans from three to seven years or longer, reducing total ownership costs.

?What Monitoring and Control Systems Optimize Performance

Modern commercial desalination systems integrate sophisticated automation enabling remote monitoring, predictive maintenance, and performance optimization. Programmable logic controllers continuously track parameters including feed pressure, permeate flow, conductivity, and differential pressure across membrane elements. Real-time data analysis identifies developing issues before they impact production, allowing proactive maintenance that minimizes downtime.

Cloud-based monitoring platforms enable facility managers to oversee system operation from any location, receiving alerts for abnormal conditions and accessing historical performance data for trend analysis. This connectivity proves particularly valuable for multi-site operations managing multiple desalination installations across different locations. Artificial intelligence algorithms can optimize operating parameters based on feed water characteristics, energy costs, and production requirements, further reducing operational expenses.

?What Configuration Options Suit Different Commercial Needs

Modular system designs allow businesses to start with capacity matching immediate requirements while maintaining expansion capability as water demand grows. Containerized units provide plug-and-play installation, arriving at sites as complete systems requiring only utility connections to commence operation. This approach significantly reduces project timelines compared to custom-engineered installations, enabling businesses to address water challenges rapidly.

Skid-mounted systems offer similar benefits while allowing greater customization of component selection and configuration. These engineered packages integrate all process components on structural frameworks designed for straightforward transportation and installation. The compact footprint proves advantageous for facilities with limited available space or requiring indoor installations for climate protection or aesthetic considerations.

?How Do Hybrid Systems Address Variable Water Quality

Facilities processing both seawater and brackish water sources benefit from hybrid configurations capable of treating water across varying salinity ranges. These systems incorporate switchable membrane arrays or parallel treatment trains optimized for different feed water characteristics. The flexibility enables operations to utilize available water sources opportunistically, minimizing energy consumption by processing lower-salinity water when available while maintaining capability for seawater desalination when necessary.

What Role Does Professional Engineering Play in System Selection?

Proper system specification requires comprehensive analysis of feed water characteristics, production requirements, space constraints, and operational preferences. Organizations like AQUAPHOR Professional provide integrated water treatment solutions combining reverse osmosis technology with complementary pre-treatment and post-treatment processes. With over 130 patents and manufacturing facilities in multiple countries, such providers deliver customized commercial desalination systems addressing specific application challenges.

Professional engineering encompasses membrane selection based on feed water salinity and fouling potential, pump sizing ensuring adequate pressure across operating ranges, and energy recovery integration maximizing efficiency. Post-treatment design addresses specific end-use requirements including remineralization for potable applications, further polishing for process water, or disinfection ensuring microbiological safety.

?What Maintenance Protocols Ensure Reliable Operation

Preventive maintenance schedules incorporating regular filter replacement, membrane cleaning, and system performance testing maximize uptime while minimizing unexpected failures. Commercial systems typically require cartridge filter changes every one to three months depending on feed water quality, with chemical cleaning of reverse osmosis membranes performed every three to six months. Proper maintenance extends membrane operational life substantially, reducing replacement costs that represent significant operational expenses.

Membrane cleaning protocols utilize specialized formulations targeting specific foulants including organic matter, biological growth, mineral scales, and colloidal deposits. The cleaning sequence typically begins with alkaline solutions removing organic fouling, followed by acidic treatments dissolving mineral scales. Proper cleaning technique restores membrane permeability close to original specifications, maintaining production capacity and water quality.

?How Do Regulatory Requirements Influence System Design

Commercial desalination systems producing potable water must comply with drinking water quality standards established by environmental and health authorities. These regulations specify maximum contaminant levels for dissolved solids, heavy metals, microorganisms, and chemical compounds. System design incorporates multiple barriers ensuring consistent compliance, including properly sized membranes, effective disinfection, and continuous water quality monitoring.

Industrial applications face discharge regulations governing concentrate disposal and equipment maintenance waste streams. Proper brine management systems dilute concentrated salt streams or implement zero-liquid discharge technology recovering minerals while minimizing environmental impact. Compliance with environmental protection requirements ensures operations avoid penalties while demonstrating corporate environmental responsibility.

Strategic Value of Commercial Desalination

Commercial desalination systems provide businesses with water supply independence, quality assurance, and operational flexibility that municipal connections cannot match. The technology addresses diverse application requirements from hospitality operations to industrial manufacturing, enabling business continuity in water-stressed regions while supporting operations requiring specific water characteristics. As membrane technology continues advancing and energy efficiency improves, commercial desalination becomes increasingly cost-competitive with traditional water sources, positioning these systems as strategic infrastructure investments rather than emergency alternatives. Organizations implementing properly engineered commercial desalination solutions gain competitive advantages through reliable water supply, reduced operational risks, and enhanced sustainability credentials.